júl . 27, 2024 19:11 Back to list

Production Processes and Quality Control in Dried Round Red Chillies Manufacturing Facilities

The World of Dried Round Red Chillies A Look at the Factories Behind Production

Dried round red chillies, known for their vibrant color and intense flavor, play a significant role in culinary traditions worldwide. These small, fiery peppers are not only a staple in many kitchens but also a vital ingredient in various cuisines, from spicy Indian curries to flavorful Mexican salsas. The production of dried round red chillies is an intricate process that involves multiple stages, including cultivation, harvesting, drying, and packaging. This article delves into the factories behind the production of dried round red chillies, highlighting their operations, challenges, and significance.

Cultivation and Harvesting

The journey of dried round red chillies begins in the fields. The cultivation of chillies requires specific climatic conditions, including warm temperatures and well-drained soil. Major producers of round red chillies include India, Mexico, and Thailand, where the peppers thrive in various agricultural settings. Farmers invest significant time and resources into nurturing their crops, from planting seedlings to managing irrigation, pest control, and fertilization.

Once the chillies reach maturity, the harvesting process begins. This is often a labor-intensive task, requiring skilled workers to handpick the ripe peppers. The harvested chillies are then transported to factories where they will undergo the drying process.

Drying Process

The drying process is critical in transforming fresh chillies into the flavorful, preserved product that consumers love. In factories, there are various methods of drying chillies, including sun-drying, hot air drying, and even microwave drying. Each method affects the flavor, color, and shelf life of the chillies.

Sun-drying is a traditional method favored in certain regions due to its low cost and ability to enhance the natural flavors of the chillies. However, it can be weather-dependent and may result in variations in quality. Hot air drying offers a more controlled environment, allowing for consistent results. It also reduces the risk of contamination from pests and moisture, which can lead to spoilage.

Once the chillies are dried, they must be sorted and graded. Factories employ quality control measures to ensure only the best chillies are packaged for sale. This involves checking for color, size, and the absence of blemishes or rot. This sorting process is essential to maintaining the quality that consumers expect.

dried round red chillies factories

Packaging and Distribution

After sorting, dried round red chillies are packaged in various forms, ranging from whole peppers to crushed chilli flakes or powdered forms. Packaging plays a crucial role in preserving the chillies' flavor and potency. Factories often use airtight containers or vacuum packs to prolong shelf life and protect against environmental factors.

Distribution is another vital aspect of the factory process. Dried round red chillies are exported globally, reaching markets far and wide. They are a key ingredient for manufacturers of sauces, spices, and snacks, as well as for restaurants and household consumers. The demand for these chillies remains high, driven by the growing popularity of spicy foods and awareness of their health benefits.

Challenges and Innovations

Despite the thriving market for dried round red chillies, factories face several challenges. These include fluctuations in weather conditions, which can impact crop yields, and increasing competition from global suppliers. Additionally, factories must navigate stringent food safety regulations to ensure the quality of their products.

In response to these challenges, many factories are embracing innovative practices. Advances in technology, such as automated sorting systems and improved drying technologies, are helping to enhance efficiency and product quality. Sustainable farming practices are also gaining traction, with some factories collaborating with farmers to promote environmentally friendly cultivation methods.

Conclusion

Dried round red chillies are more than just a flavorful addition to meals; they are a product of intricate processes and dedicated efforts between farmers and factories. As international demand continues to grow, the industry adapts and evolves, ensuring that these delicious chillies remain a beloved ingredient for future generations. Whether enjoyed in a home-cooked meal or as part of a gourmet dish in a restaurant, the journey of dried round red chillies from farm to factory is a testament to their enduring appeal and importance in global cuisine.

-

Ghost Chili Pods2: AI-Optimized Heat Solutions

NewsAug.01,2025

-

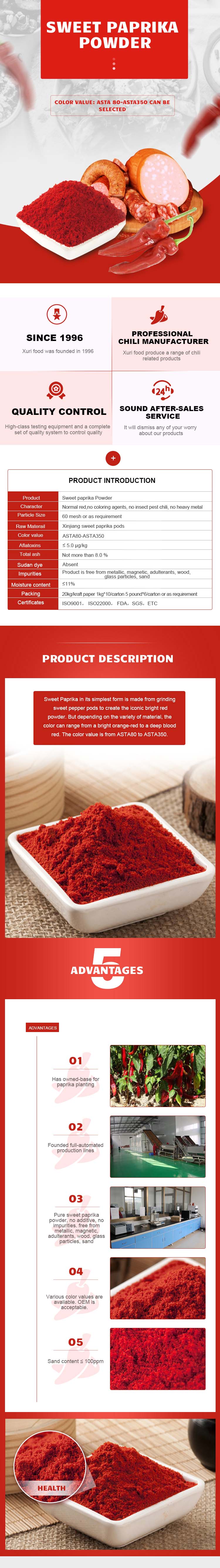

Sweet Paprika Spice - Natural, Sweet & Smoky Flavor Enhancer

NewsJul.31,2025

-

Ghost Chili Powder: World's Hottest Spice for Bold Dishes

NewsJul.31,2025

-

Premium Chili Powder-600: Mild Heat, Pure Flavor

NewsJul.30,2025

-

Premium Ghost Chili Powder2 - Extreme Heat & Pure Flavor

NewsJul.30,2025

-

Premium Shishito Paprika & Red Pepper Powder for Culinary Use

NewsJul.29,2025