Oct . 31, 2024 05:01 Back to list

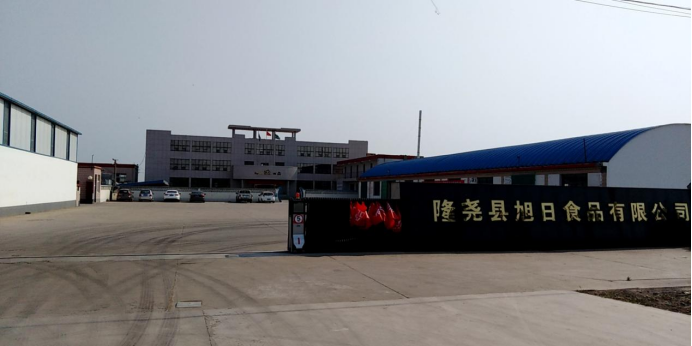

red paprika manufacturer

The Art and Science of Red Paprika Production

Red paprika, a vibrant spice beloved across various cuisines, has become a staple in kitchens around the world. Its rich flavor profile and bright color not only enhance dishes but also provide numerous health benefits. For manufacturers in the paprika industry, understanding the nuances of production is essential to thriving in this competitive market.

At the heart of paprika manufacturing lies the Capsicum annuum plant, which is cultivated primarily for its fruit. The journey from farm to table begins with the careful selection of seeds, as the variety of pepper used directly influences the spice's flavor, heat level, and color. Common varieties include sweet, smoked, and hot paprika, each offering distinct characteristics that cater to different culinary needs.

The Art and Science of Red Paprika Production

Once harvested, the process of transforming fresh peppers into the powdery spice familiar to many involves several steps. The peppers must be cleaned, blanched, and then dried. This drying process is crucial as it concentrates the flavors and turns the peppers into a shelf-stable product. Depending on the manufacturer, various drying methods may be employed, including air drying, sun drying, and using industrial dehydrators. Each method may impart slight differences in flavor and color, making it vital for manufacturers to choose the right technique based on their target market.

red paprika manufacturer

After drying, the peppers are ground into a fine powder. Quality control at this stage is paramount; manufacturers must ensure that the final product is not only consistent in texture but also free from contaminants. Advanced machinery may be utilized for grinding, but traditional stone grinding still remains popular among producers who value the artisanal approach to spice-making.

Packaging is another critical component of the paprika manufacturing process. Proper packaging preserves the spice’s aroma and prevents moisture from affecting its quality. Manufacturers often use glass jars, plastic containers, or vacuum-sealed bags to enhance shelf life and appeal to consumers. Clear labeling that includes information about the product's origin, heat level, and best uses helps to engage customers and instill confidence in the product's quality.

As consumer preferences evolve, paprika manufacturers are increasingly focusing on sustainability and organic production methods. Many farmers are adopting eco-friendly practices, such as crop rotation and natural pest control, to minimize environmental impact. Additionally, the rise of health-conscious consumers has led to a demand for organic paprika, prompting manufacturers to seek certified organic sources.

In summary, the production of red paprika is a meticulous process that blends agricultural expertise with an understanding of consumer demands. By focusing on quality at every stage—from cultivation to packaging—paprika manufacturers can ensure that their products not only meet but exceed market expectations. As the popularity of this vibrant spice continues to grow, the industry's ability to adapt and innovate will be key to its success.