Dec . 25, 2024 07:13 Back to list

Choosing the Best Supplier for Dried Chili Flakes Production

The Process of Creating High-Quality Dried Chilli Flakes A Guide for Suppliers

Chilli flakes have become an essential ingredient in a multitude of cuisines around the world, cherished for their ability to enhance flavors and add a distinctive heat. As the demand for dried chilli flakes continues to rise, suppliers must focus on producing high-quality products that meet the expectations of chefs and home cooks alike. This article will explore the process of making dried chilli flakes, from sourcing raw materials to packaging the final product, and highlight the importance of quality at every step.

Sourcing the Right Peppers

The journey of creating premium dried chilli flakes begins with the selection of the right type of chillies. There are countless varieties available, each contributing unique flavors and heat levels. For suppliers, sourcing high-quality chillies is paramount. This often involves establishing relationships with local farmers or growers who understand the importance of cultivating peppers without the use of harmful pesticides or chemicals. Popular varieties like cayenne, paprika, and crushed red pepper offer different flavor profiles, and suppliers should carefully consider their clientele’s preferences to choose the right ones.

Harvesting and Drying

Once the chillies are harvested, the next step is drying. This process is crucial as it not only extends the shelf life of the product but also concentrates the flavors. There are several drying methods suppliers can choose from, including air drying, sun drying, and using industrial dehydrators. Each method has its advantages; for example, sun drying can enhance the natural sweetness of the chillies, while controlled dehydrators can ensure consistent results regardless of weather conditions.

Once dried, the chillies should be stored in a cool, dry place to preserve their flavor and prevent mold growth. Proper storage is essential to maintain product quality and freshness.

Grinding and Flaking

After drying, the chillies are ready to be ground into flakes. The grinding process should be carefully managed; over-processing can lead to a powdery consistency rather than the desired flaky texture. Suppliers often use specialized machinery to ensure uniformity in size, which is important for culinary applications. The ideal chilli flakes should have a balanced mix of seeds and bits of the pepper, enabling them to provide both flavor and visual appeal when used in dishes.

making dried chilli flakes supplier

Quality Control

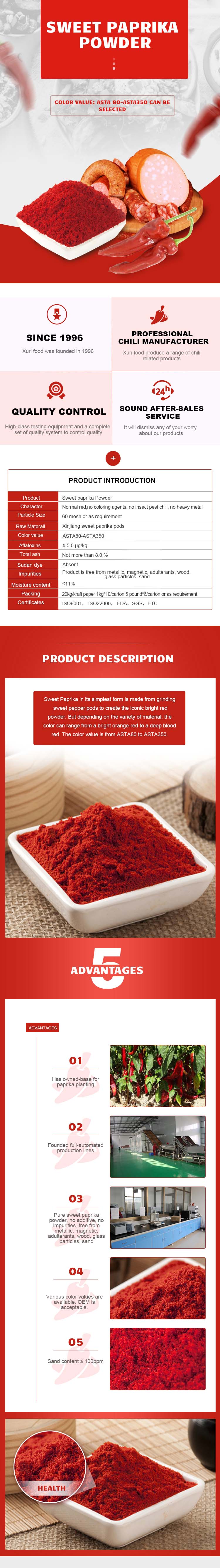

Quality control is an integral part of the production process. Regular testing for moisture content, flavor potency, and the presence of contaminants is essential to ensure that the final product is safe for consumption and meets industry standards. Suppliers must implement stringent testing protocols, especially if they are exporting their products to international markets, where regulations can be more rigorous.

Moreover, the appearance of the chilli flakes plays a significant role in customer satisfaction. Suppliers should aim for vibrant, red flakes that reflect the quality of the peppers from which they are made. Consistency in color and texture is key to building a reputable brand.

Packaging and Distribution

Finally, packaging is crucial in protecting the integrity of dried chilli flakes. Using vacuum-sealed bags or airtight containers can help preserve freshness and extend shelf life. Suppliers should also consider eco-friendly packaging options, as sustainability is becoming increasingly important to consumers.

Once packaged, establishing efficient distribution channels is essential. Partnering with local grocery stores, restaurants, and online marketplaces can help suppliers reach a broader audience. Clear labeling that includes heat levels, flavor profiles, and suggested uses can assist consumers in making informed choices.

Conclusion

As the popularity of dried chilli flakes continues to soar, suppliers have a unique opportunity to carve out their niche in this burgeoning market. By focusing on sourcing quality raw materials, implementing careful processing methods, ensuring rigorous quality control, and adopting effective packaging solutions, suppliers can offer exceptional products that meet the needs of their customers. With the right approach, anyone involved in the supply of dried chilli flakes can succeed in this dynamic and flavorful industry.