Ago . 12, 2025 01:20 Back to list

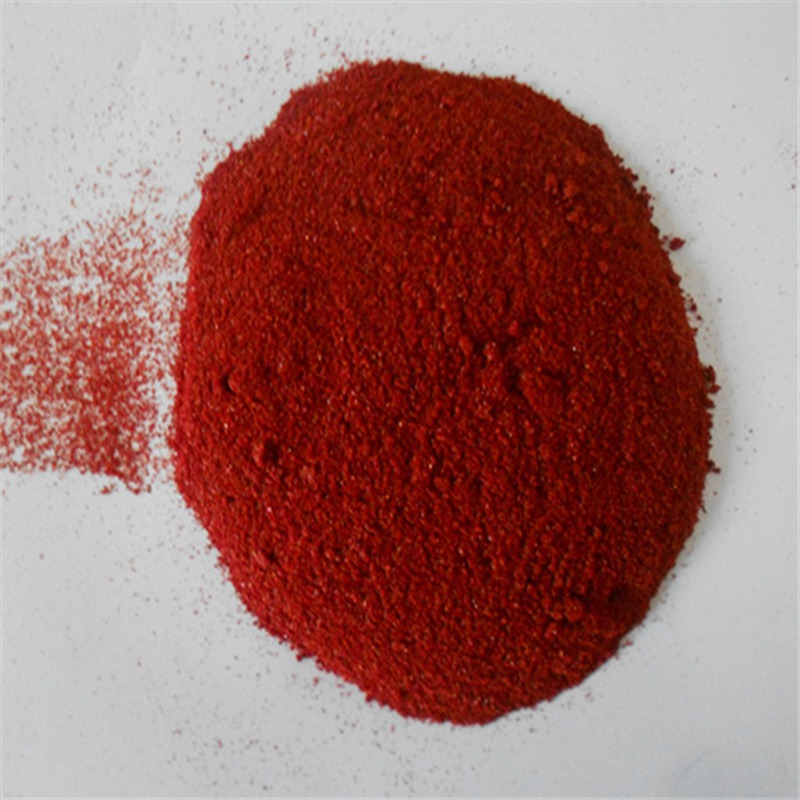

Premium Sweet Paprika Pimenton: Rich Flavor & Mild Heat

Understanding the Market Dynamics of Premium Paprika

The global spice market is experiencing robust growth, driven by increasing consumer demand for authentic flavors, natural ingredients, and functional foods. Within this dynamic landscape, sweet paprika pimenton stands out as a highly sought-after ingredient, prized for its vibrant color, nuanced flavor profile, and versatility. Industry trends indicate a significant shift towards high-quality, traceable ingredients, with a particular emphasis on color stability and consistent sensory attributes. Beyond its culinary appeal, the demand for natural food colorants and antioxidants derived from paprika is also on the rise, influencing procurement strategies across the food and beverage sectors. This evolution necessitates suppliers to not only meet stringent quality standards but also to innovate in processing techniques to preserve the inherent qualities of the capsicum annuum fruit.

Furthermore, the market for specialty peppers, including variants like sweet chili paprika, is expanding due to culinary experimentation and the fusion of global cuisines. Consumers and food manufacturers are increasingly discerning, looking for specific Pungency Units (Scoville Heat Units, SHU) and Astaxanthin values, which impacts how paprika is sourced, processed, and blended. Sustainability and ethical sourcing practices are no longer mere buzzwords but critical factors influencing purchasing decisions, prompting leading suppliers to implement transparent supply chains and adhere to responsible agricultural practices. This comprehensive approach ensures that the end product, such as premium Sweet paprika powder, not only delivers on flavor and color but also aligns with the evolving ethical and environmental standards of the modern food industry.

The Meticulous Manufacturing Process of Sweet Paprika Powder

The production of high-quality sweet paprika pimenton powder involves a sophisticated multi-stage process, meticulously designed to preserve its color, flavor, and nutritional integrity. It begins with the careful selection of mature Capsicum annuum fruits, primarily sourced from regions renowned for their optimal growing conditions, ensuring the finest raw material quality. Following harvesting, the peppers undergo thorough cleaning to remove any impurities. The most critical stage is drying, which can be achieved through traditional sun-drying methods, which enhance the smoky notes characteristic of pimenton, or controlled mechanical drying to ensure consistent moisture content and color retention, crucial for industrial applications. This process must be carefully managed to prevent mold growth while preserving the delicate carotenoids responsible for the vibrant red hue.

Fig 1: Automated sorting and cleaning equipment ensuring raw material purity.

Once dried to an optimal moisture level, the peppers are destemmed and deseeded, removing any components that could impart undesirable flavors or textures. This meticulous preparation is followed by grinding, typically using stone mills or advanced pulverizers to achieve a fine, consistent powder (e.g., 60-80 mesh) without generating excessive heat, which can degrade color and flavor compounds. Post-grinding, the powder undergoes rigorous sifting to ensure uniform particle size and remove any remaining coarse material. Sterilization is a crucial step for food safety, often achieved through validated steam sterilization processes or, in some cases, gamma irradiation, to significantly reduce microbial load while maintaining the product’s organoleptic properties. Adherence to international standards such as ISO 22000, HACCP, and FDA guidelines is paramount throughout this entire process, ensuring a safe, consistent, and high-quality Sweet paprika powder for global distribution.

Technical Parameters & Quality Assurance

The performance and application suitability of sweet paprika pimenton are primarily defined by its technical specifications. Key parameters include color value (measured in ASTA units), moisture content, particle size (mesh), and microbiological purity. For products like sweet chili paprika, capsaicin content (Scoville Heat Units, SHU) also becomes a critical differentiating factor, although traditional sweet paprika has negligible heat. Our production strictly adheres to international quality assurance protocols, including robust testing at every stage, from raw material inspection to final product release. This commitment is underpinned by certifications such as ISO 9001, ISO 22000 (Food Safety Management System), and HACCP (Hazard Analysis and Critical Control Points), alongside compliance with FDA regulations for food-grade ingredients.

Fig 2: Laboratory testing for ASTA color value and microbial analysis.

To provide a clear understanding of our Sweet paprika powder's quality, we present a typical specification profile. These parameters ensure that our product delivers consistent performance, whether used as a natural colorant, a flavor enhancer, or a primary spice ingredient in various food formulations. Our in-house laboratories utilize advanced analytical techniques, including spectrophotometry for ASTA color, Karl Fischer titration for moisture, and standard microbiological plate counts to guarantee safety and shelf-life stability.

| Parameter | Specification | Testing Method |

|---|---|---|

| ASTA Color Value | 60-140 ASTA (customizable) | AOAC 971.26 / Spectrophotometry |

| Moisture Content | ≤ 9.0% | ISO 939 / Karl Fischer |

| Particle Size | Min 95% through 60 Mesh (customizable) | Sieve Analysis |

| Total Plate Count | ≤ 10^5 cfu/g | ISO 4833 |

| Yeast & Mold | ≤ 10^3 cfu/g | ISO 21527 |

| Coliforms | ≤ 10^2 cfu/g | ISO 4831 |

| Salmonella | Negative in 25g | ISO 6579 |

| Aflatoxins (B1, B2, G1, G2) | ≤ 5 ppb total | HPLC |

Application Scenarios & Technical Advantages

The versatility of premium sweet paprika pimenton powder makes it an indispensable ingredient across a wide array of food industry applications. Its primary utility lies in its dual function as a natural food colorant and a distinct flavor enhancer. In the processed meat industry, it is crucial for products like sausages, cured meats, and charcuterie, where it contributes to an appealing reddish hue and a rich, savory depth. For the snack food sector, it is extensively used in seasonings for potato chips, extruded snacks, and crackers, providing both visual appeal and a characteristic mild, sweet, and slightly smoky flavor. The growing demand for clean-label ingredients has further propelled paprika's adoption as an alternative to artificial colorings.

Fig 3: Paprika powder being incorporated into a seasoning blend for snack products.

Beyond these, Sweet paprika powder finds significant application in sauces, marinades, soups, and ready meals, imparting consistent color and robust flavor profiles without introducing heat, unlike its counterpart sweet chili paprika. The technical advantages of our product stem from our stringent processing controls. We ensure superior color stability, critical for products with longer shelf lives, by minimizing oxidation during drying and grinding. Our low moisture content (typically ≤ 9.0%) significantly extends the product’s shelf life and prevents caking, offering operational benefits for manufacturers. Furthermore, the microbiological purity, achieved through validated sterilization methods, reduces the risk of spoilage and ensures compliance with the most rigorous food safety standards globally, enhancing product integrity and consumer confidence.

Strategic Partnerships & Tailored Solutions

Selecting the right supplier for critical ingredients like sweet paprika pimenton is a strategic decision for B2B entities. While specific manufacturer comparisons are complex due to proprietary processes, key differentiators include a supplier's commitment to consistent quality, supply chain transparency, and capabilities in customization. Our company distinguishes itself through decades of experience in the spice industry, establishing ourselves as a reliable partner. We emphasize long-term relationships built on trust, demonstrated by our consistent delivery of products that meet or exceed client specifications. Our extensive network of certified growers ensures a sustainable and high-quality raw material supply, even amidst fluctuating market conditions.

Fig 4: Secure packaging for bulk Sweet Paprika Powder ensuring product integrity during transit.

Understanding that each client has unique requirements, we offer comprehensive customized solutions for our Sweet paprika powder. This includes tailoring ASTA color values (e.g., 60 ASTA, 80 ASTA, 120 ASTA) to match specific product formulations or branding needs, providing different mesh sizes for optimal texture and dispersion, and offering various packaging formats, from bulk bags for industrial clients to smaller, food-service compliant packs. Our R&D team works closely with clients to develop bespoke blends, integrating sweet chili paprika or other spices if a particular flavor profile is desired. A notable application case involves a major European food manufacturer for whom we developed a high-ASTA, low-microbial paprika powder, which significantly improved the visual appeal and extended the shelf life of their premium sausage range, leading to a 15% increase in market penetration. This collaborative approach underscores our commitment to not just supplying ingredients, but providing integrated solutions that drive client success.

Trustworthiness & Customer Support

Building and maintaining trust is fundamental in B2B relationships. Our commitment to trustworthiness is reflected in our transparent operations, comprehensive quality control, and robust customer support. We provide detailed certificates of analysis (COAs) with every batch of Sweet paprika powder, confirming adherence to specifications and relevant certifications (e.g., Kosher, Halal, Organic where applicable). Our standard lead time for deliveries is typically 2-4 weeks for standard orders, with expedited options available for urgent requirements, ensuring reliable supply chain management for our partners. We offer a comprehensive quality guarantee, ensuring that all products meet the agreed-upon specifications and are free from defects. In the unlikely event of a discrepancy, our dedicated customer service team is prepared to address concerns promptly and efficiently, adhering to established protocols for complaint resolution and product returns.

Frequently Asked Questions (FAQ)

Q: What is the shelf life of your Sweet paprika powder?

A: Our Sweet paprika powder, when stored in a cool, dry place away from direct sunlight and strong odors, typically has a shelf life of 24 months from the manufacturing date. This is ensured by our low moisture content and sterile packaging.

Q: Is your sweet paprika pimenton non-GMO and allergen-free?

A: Yes, our Sweet paprika powder is naturally non-GMO. It is also free from common allergens such as gluten, nuts, soy, and dairy. Our production facilities follow strict allergen control programs to prevent cross-contamination.

Q: Can you provide samples for R&D purposes?

A: Absolutely. We understand the importance of product testing. We are happy to provide samples of our Sweet paprika powder and other variants like sweet chili paprika upon request to support your research and development efforts.

Q: What are your packaging options for bulk orders?

A: For bulk orders, we offer various packaging options, including multi-ply paper bags, fiber drums, and bulk totes, typically ranging from 25 kg to 1000 kg, designed to maintain product integrity and facilitate efficient handling for industrial clients. Customized packaging solutions are also available upon discussion.

References

- Smith, J. et al. "Advances in Spice Processing Technologies for Enhanced Flavor and Safety." Journal of Food Science and Technology, 2022.

- European Spice Association (ESA) Quality & Hygiene Guidelines for Paprika.

- Jones, A. & Brown, R. "The Role of Natural Colorants in the Modern Food Industry." Food Chemistry Review, 2021.

- Global Market Insights. "Paprika Market Size, Share & Trends Analysis Report." 2023.

- United States Food and Drug Administration (FDA) CFR Title 21 - Food and Drugs.

This is the last article

-

Premium Sweet Paprika Pimenton: Rich Flavor & Mild Heat

NewsAug.12,2025

-

Vibrant Paprika Koral: Premium Culinary Red Pepper

NewsAug.11,2025

-

Pul Biber Paprika: Mildly Spicy Ground Red Pepper

NewsAug.10,2025

-

Fiery Ghost Chili Powder: Intense Heat for Culinary Adventures

NewsAug.09,2025

-

Premium Chili Powder-70: 80,000 SHU Heat for Bold Flavor

NewsAug.08,2025

-

Hot Paprika Crushed Red Pepper | Intense Spice & Flavor

NewsAug.07,2025